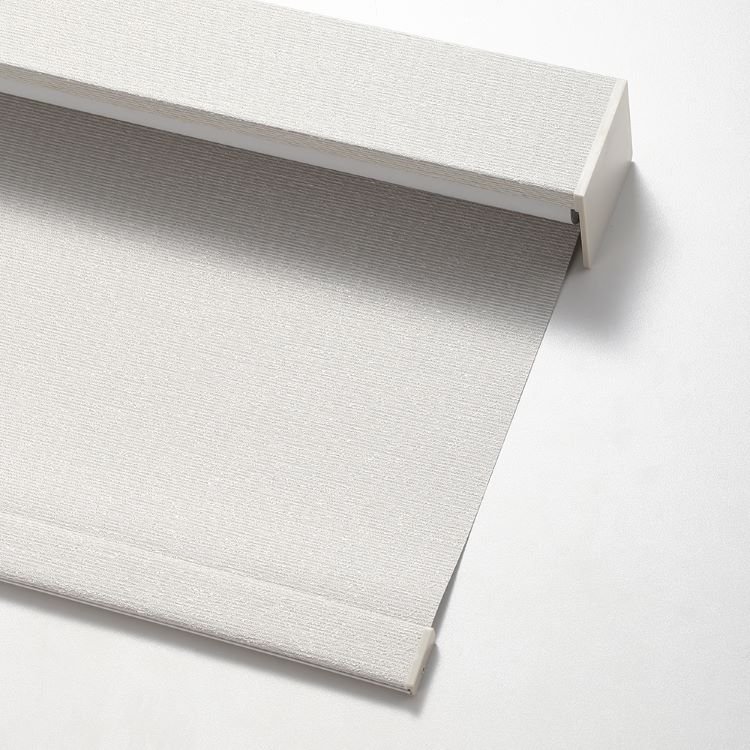

Custom zebra blinds look modern and control light very well, making them a great choice for many business projects. When buying in bulk, you need to know all the ways to customize them.

Buying custom zebra blinds wholesale for commercial projects requires understanding customization options like opacity, colors, and motorization. Material quality and operating mechanisms greatly impact performance and cost. Shadesmart offers comprehensive support for precise measurements, quality control, streamlined ordering, and efficient installation.

I know that choosing the right window treatment for commercial projects is about balancing aesthetics, functionality, and budget. Custom zebra blinds are a fantastic option, but buying them wholesale needs a detailed plan. This guide helps me ensure my clients get exactly what they need, every time.

What customization options are available for wholesale zebra blinds?

Are you wondering how much you can really change zebra blinds when buying them in large quantities? There are many ways to make them fit your specific project.

Customization options for wholesale zebra blinds include fabric opacity (sheer, light-filtering, blackout), a wide range of colorways and patterns, various headrail and bottom bar finishes, and different operating mechanisms like manual chain, cordless, or full motorization with smart home integration.

From my experience, the beauty of custom zebra blinds for commercial projects lies in their versatility. There are many customization options available, making them suitable for diverse design requirements. First, fabric opacity is a key choice. You can select sheer fabrics for maintaining views and maximizing natural light while still offering some privacy. Light-filtering options provide good privacy and diffused light, perfect for offices or common areas. Blackout fabrics offer complete privacy and light blockage, ideal for conference rooms, hotel bedrooms, or media rooms. Shadesmart offers all these opacities to meet specific project needs. Second, the range of colorways and patterns is extensive. Beyond standard neutrals, you can find various textures, patterns, and bold colors that complement a brand's aesthetic or interior design scheme. The right color choice can significantly impact the room's mood and visual appeal. Third, hardware finishes are important for a cohesive look. Headrails and bottom bars can come in different colors (white, black, silver, bronze) and finishes (matte, brushed) to seamlessly blend with existing window frames or interior decor. Fourth, operating mechanisms offer significant customization. Options include standard continuous cord loops, child-safe cordless systems (ideal for schools or healthcare), and advanced motorization. Motorized options can range from simple remote control to integration with building management systems (BMS), providing ultimate convenience and energy efficiency, a specialty of Shadesmart.

| Customization Option | Description | Project Impact |

|---|---|---|

| Fabric Opacity | Sheer (view/light), Light-filtering (privacy/diffused light), Blackout (full privacy/darkness). | Controls light, privacy, and ambiance for specific room functions. |

| Colorways & Patterns | Wide selection of solid colors, textures, and designs. | Matches brand aesthetics, enhances interior design, impacts mood. |

| Hardware Finishes | Headrail and bottom bar colors/finishes (e.g., white, black, silver, matte). | Creates a cohesive look, blends with architectural elements. |

| Operating Mechanisms | Manual (cord loop, cordless) vs. Motorized (remote, smart home, BMS). | Influences user convenience, safety, energy efficiency, and cost. |

| Cassette/Valance Style | Open roll vs. enclosed cassette for a finished, sleek look. | Affects aesthetics and how the blind integrates with the window. |

| Hem Bar Style | Standard (exposed) vs. Fabric-wrapped. | Minor aesthetic detail, contributes to overall finish. |

How do material quality and operating mechanisms impact performance and cost?

Are you wondering if choosing better materials or different ways to operate blinds really matters for their long-term use and your budget? Yes, it makes a big difference.

Material quality in zebra blinds impacts durability, UV protection, light control, and long-term appearance, affecting replacement costs. Operating mechanisms (manual vs. motorized) influence convenience, safety, integration capabilities, and initial investment versus ongoing energy savings.

I know that making smart choices about material quality and operating mechanisms significantly impacts both the performance and the overall cost of a project. For zebra blinds, it is no different. First, consider material quality. A high-quality fabric will offer superior durability, meaning it resists fading, fraying, and warping over time. This translates into infrequent replacements, saving my client money in the long run. Better materials also provide more effective UV protection, safeguarding interior furnishings from sun damage. Furthermore, the quality of the fabric directly influences light control. Higher-grade fabrics ensure a consistent light filtering or blackout effect across the entire blind. Cheaper materials might have inconsistencies or degrade faster. Shadesmart focuses on durable, high-performance fabrics. Second, the operating mechanism has a profound effect. A manual continuous cord loop system is generally the most cost-effective upfront. However, it requires manual effort, can be a child safety hazard in some settings, and might not be ideal for hard-to-reach windows. Cordless systems are safer and look cleaner but often cost slightly more. Motorized systems, while having a higher initial cost for the motor and controls, offer unparalleled convenience and precise control, which can be linked to energy management systems. The investment in motorization yields long-term benefits in energy savings, increased comfort, and operational efficiency, especially in commercial spaces with many windows. The choice balances upfront cost with long-term utility, safety, and operational savings.

| Aspect | Description | Impact on Performance | Impact on Cost |

|---|---|---|---|

| Fabric Durability | Resistance to fading, fraying, warping, general wear and tear. | Extends lifespan, maintains appearance. | Higher initial cost, lower long-term replacement/maintenance. |

| UV Protection | Ability of fabric to block harmful ultraviolet rays. | Protects interior furnishings, reduces heat gain. | Quality fabrics may cost more, but save on property damage. |

| Light Control Consistency | Uniformity of light filtering or blackout effect across the blind. | Enhances comfort, glare reduction, and functionality. | Higher for consistent, high-performance fabrics. |

| Manual Mechanisms | Continuous cord loop, cordless systems. | Requires manual operation, varying safety/cleanliness. | Lower initial cost. |

| Motorized Mechanisms | Remote, smart home/BMS integration, battery/wired options. | High convenience, precision, energy integration, safety. | Higher initial cost, potential long-term energy savings. |

| Aesthetic Retention | How well the material maintains its original look over time. | Preserves interior design, contributes to professional image. | Cheaper materials degrade faster, incurring replacement costs. |

What is the process for ensuring accurate measurements and quality control for bulk orders?

Are you concerned about getting thousands of blinds that fit perfectly and look great? A good process is essential for large orders.

Ensuring accurate measurements for bulk orders involves rigorous site verification and detailed specification sheets. Quality control requires multi-stage inspections: raw material checks, in-process production monitoring, and final pre-shipment inspections by qualified personnel or third parties.

I know that for bulk orders, even a small error in measurement or quality control can lead to huge problems and significant cost overruns. So, I insist on a rigorous process. First, for accurate measurements, site verification is non-negotiable. While clients provide initial measurements, I advise a final, professional measure on-site to account for any architectural nuances or installation challenges. We use detailed specification sheets that document every single measurement precisely, down to fractions of an inch, and specify allowances. This minimizes errors. Second, quality control for bulk orders is implemented at multiple stages. It begins with raw material inspection. Our teams, like Shadesmart’s dedicated QC personnel, check incoming fabrics, hardware, and motors to ensure they meet specified standards before production even begins. Third, in-process quality control involves continuous monitoring during manufacturing. This means checking cuts, stitching, assembly, and motor function at various points along the production line. Any deviations are flagged and corrected immediately. Fourth, a final pre-shipment inspection (PSI) is conducted on a statistically significant sample of the finished blinds. This comprehensive check covers dimensions, fabric quality, motor function, hardware integrity, and packaging. Any identified issues trigger a full review and required rework. This multi-layered approach ensures every blind meets the exact design specifications and quality benchmarks my clients expect from Shadesmart.

| Process Step | Description | Benefit for Bulk Orders |

|---|---|---|

| Site Verification (Measurements) | Professional on-site measurement and final confirmation of dimensions. | Eliminates measurement errors, ensures perfect fit for every window. |

| Detailed Spec Sheets | Comprehensive documentation of every dimension, material, and component. | Provides clear instructions, minimizes misinterpretations. |

| Raw Material Inspection | Quality check of all incoming fabrics, hardware, and motors. | Prevents foundational defects from entering production. |

| In-Process QC | Ongoing monitoring and checks during each stage of manufacturing. | Catches and corrects errors early, reduces waste and rework. |

| Pre-Shipment Inspection (PSI) | Final comprehensive check of a sample of finished products before shipping. | Guarantees overall product quality and compliance for the entire shipment. |

| Packaging Inspection | Verification of packaging integrity and protective measures. | Ensures products arrive at site undamaged, ready for installation. |

How can businesses streamline ordering and installation of custom zebra blinds?

Are you looking for ways to make buying and putting in custom zebra blinds for your business easier? A smooth process saves a lot of time and hassle.

Businesses can streamline ordering and installation of custom zebra blinds by partnering with a comprehensive supplier like Shadesmart, utilizing digital specification tools, consolidating orders, ensuring clear communication, and working with experienced installers.

I know that for large commercial projects, streamlining the ordering and installation process for custom zebra blinds saves significant time and reduces potential headaches. First, partnering with a comprehensive supplier like Shadesmart is crucial. A supplier that handles everything from detailed product configuration and manufacturing to logistics and direct delivery simplifies the entire chain. They act as a single point of contact, making communication efficient. Second, utilizing digital specification and ordering tools can accelerate the process. Online portals or dedicated software for entering measurements, selecting options, and generating quotes reduce manual errors and speed up order placement. Shadesmart can provide this level of technological support. Third, consolidating orders whenever possible simplifies logistics and often secures better pricing. Placing one large order for an entire project, rather than multiple small ones, means fewer shipments to track, fewer invoices to process, and less administrative work. Fourth, maintaining clear and proactive communication with the supplier throughout the project lifecycle is essential. Regular updates on production status, shipping schedules, and potential challenges help manage expectations and prevent surprises. Finally, working with experienced installers who are familiar with custom zebra blinds and, ideally, the specific products from your chosen supplier, ensures efficient and correct installation. Proper installation is key to both performance and longevity. These steps, combined, create a much smoother journey from initial design to final installation.

| Streamlining Strategy | Description | Benefit for Businesses |

|---|---|---|

| Comprehensive Supplier Partnership | Working with a single provider managing entire process (spec to delivery). | Simplified communication, reduced coordination effort, holistic support. |

| Digital Specification Tools | Using online platforms or software for measurements, options, and quotes. | Speeds up ordering, reduces manual errors, improves accuracy. |

| Order Consolidation | Grouping all project blind requirements into one large order. | Saves on shipping, often secures better volume pricing, fewer logistical touchpoints. |

| Clear Communication | Regular and proactive updates and feedback loops with the supplier. | Manages expectations, avoids delays, resolves issues quickly. |

| Experienced Installers | Utilizing professionals familiar with custom zebra blinds and product range. | Ensures efficient, correct, and high-quality installation. |

| Project Management Support | Supplier offers dedicated project management to oversee the order. | Provides a single point of contact, ensures smooth execution. |

Conclusion

Buying custom zebra blinds wholesale requires understanding customization and the impact of material quality on performance and cost. Businesses must ensure accurate measurements and multi-stage quality control for bulk orders. Partnering with a comprehensive supplier like Shadesmart streamlines ordering and installation, guaranteeing project success and client satisfaction.